The startup robodev from Karlsruhe has won the 3rd place at the 6th Venture Capital Pitch. Andreas Bihlmaier, CEO & Co-Founder, tells us about industry 4.0, his startup robodev and its role within this current development.

In February, the startup robodev from Karlsruhe won the third place in the 6th Venture Capital-Pitch in the L-Bank Rotunda in Stuttgart. According to the motto „Best of Baden-Württemberg“, the most innovative High-Tech-Founders of the state presented their business concepts at the 6th edition of the Venture Capital-Pitch. About 220 guests from the German-speaking area chose their favourites among the pitching startups.

All startups that have their headquarter in Baden-Württemberg, a focus on IT, Life Science or Technology, and a capital requirement of more than 500.000 Euro, were allowed to apply.

In your own words, what does “industry 4.0” mean?

In my opinion, the most important aspect of “industry 4.0” is the rejuvenation of the old economy, as which industrial manufacturing has been perceived before the term appeared on the (political) agenda in 2011. Along with this shift in the public perception, people with a background in fields that were historically more remote to industrial automation, turned their attention on this sector. For example, while it was rare for computer scientists to perceive manufacturing and robotics as one of the fields-to-be-in, it has become quite normal to find talented students interested in making their impact in this area.

What does the startup robodev do?

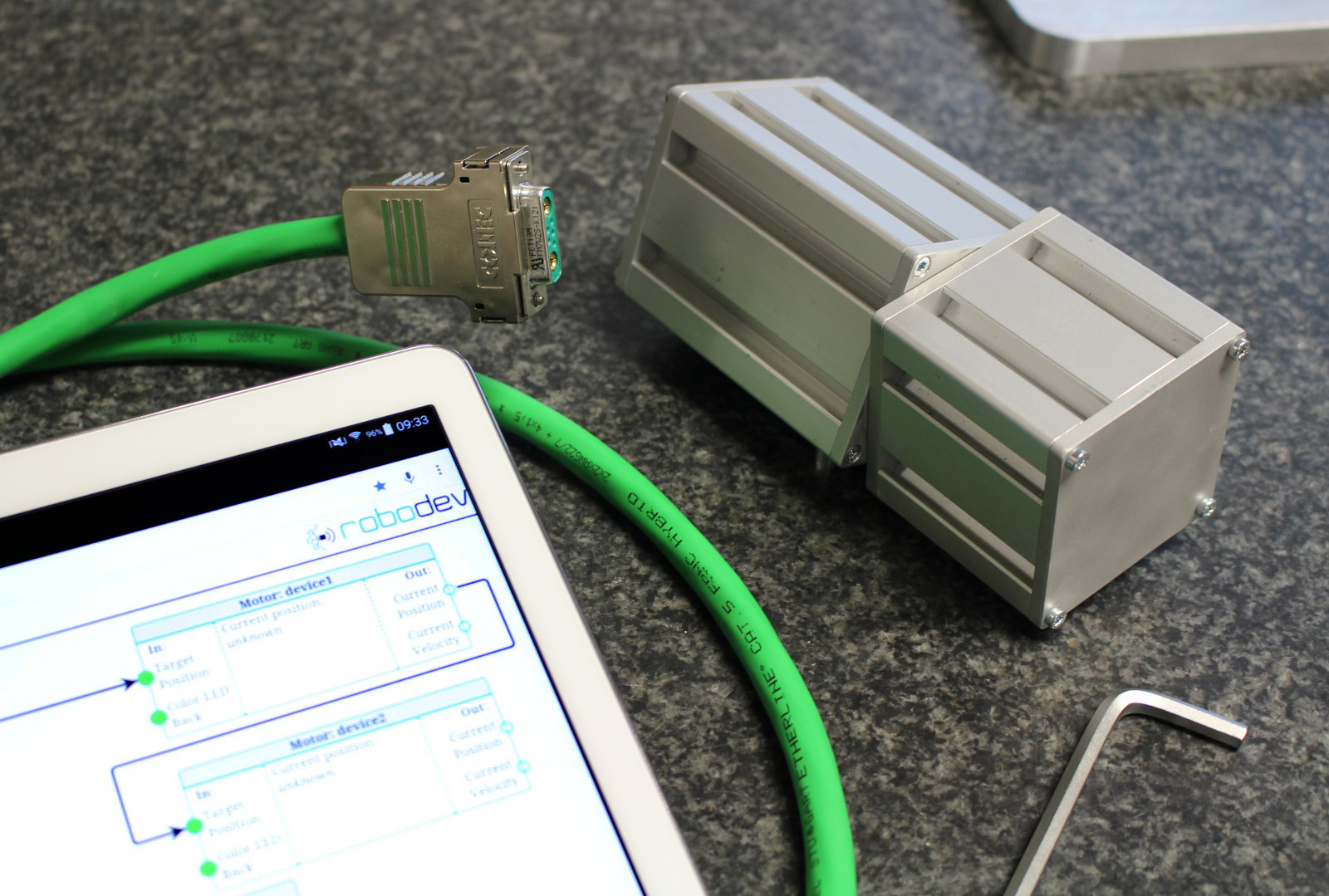

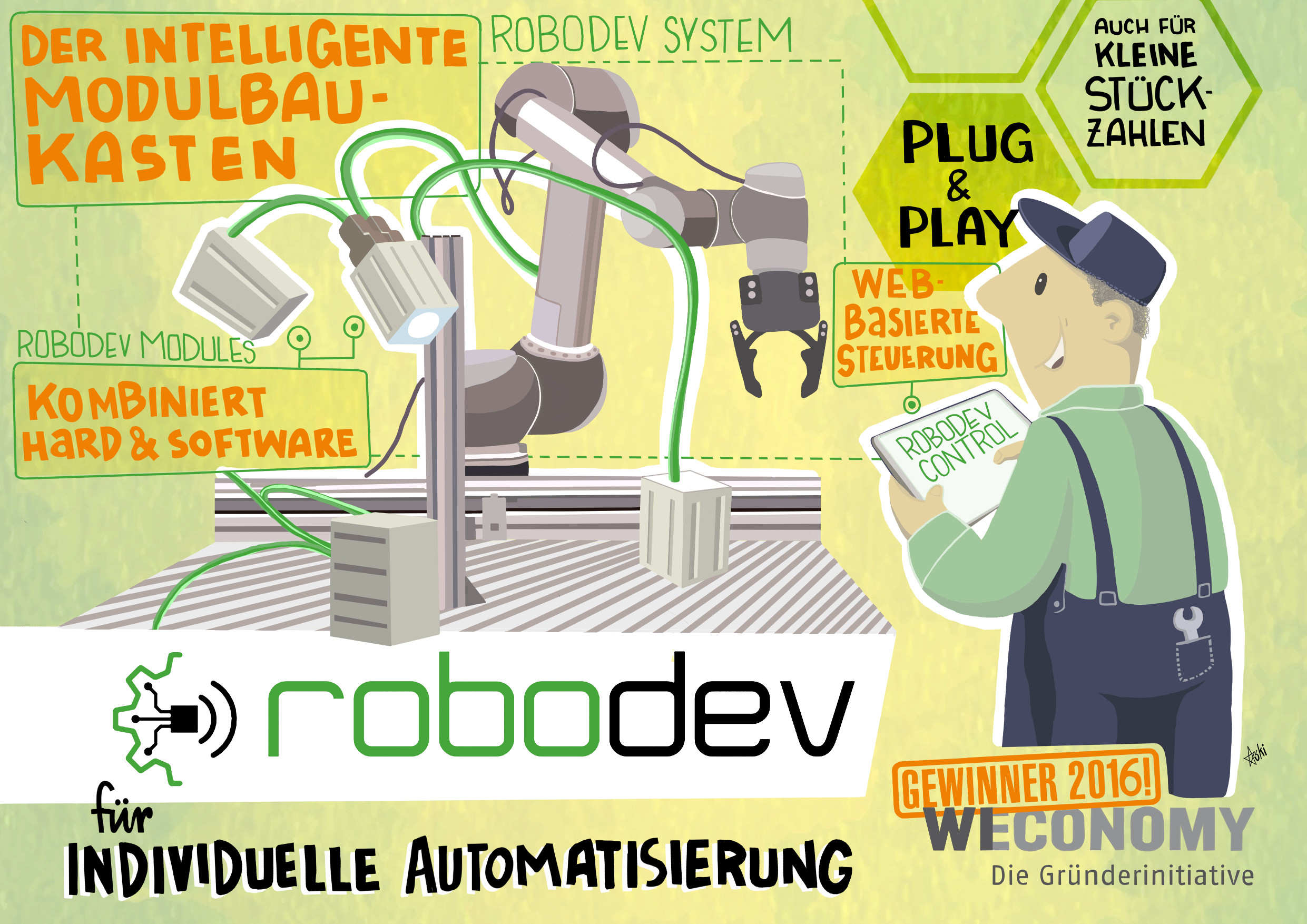

The startup robodev provides a set of easy-to-use hardware modules together with an intuitive control software that enables people to build individual automation solutions inhouse. Our goal is to enable our customers to adapt their production to megatrends such as shortened product life cycles, mass customization and volatile markets in an agile manner.

Today, 75 % of production processes are manual or have only a low level of automation – even in Germany. In order to remain competitive in the globalized economy, the workers must be supported in their value creating activities in the manner required for the individual production circumstances. The robodev solution is individual assistance systems, which can be directly added to the existing production facilities and which are economically viable even for small quantities. Combined with the novelty that no external service provider is required for setup and retooling of the robodev system, it becomes feasible for workers and planers to directly translate their process know-how (motivation, creativity) into a partially automated process (quality, efficiency).

How does the startup robodev contribute to the industry 4.0 in Germany?

The robodev system is a very tangible example of innovation in the manufacturing sector that brings a concrete value to our customers.

Since we built on established industry standards and take important aspects of “Industry 4.0” products, such as connectivity, software-centric automation and new business models, into consideration for every part of the system, we add to the cyber-physical foundation on which the 4th industrial revolution will be built. For this reason, robodev is also featured as an example of a practical use-case by the “Lab Network Industrie 4.0” (LNI4.0).

The Lab Network Industrie 4.0 has the goal to provide “test environments” for industrial applications. In other words, it is about showing practical examples of I4.0, especially those that can be realized with SMEs.

Where did the idea for robodev come from?

Once upon a time … there were three PhD students in the Institute for Process Control and Robotics (IPR) at the Karlsruhe Institute for Technology (KIT) and asked themselves whether it has to take so much effort and time to built up even basic automation systems. A task that has to be undertaken frequently in an academic research setting with a multitude of national and European projects.

No! Things can be made much easier.”

Given the joint interdisciplinary background of the later robodev founders – and after a lot of work – the answer was a definite “No! Things can be made much easier”. The main point being the proper integration, in hardware and in software, of, thus far, detached system components. After showing our early prototypes to several production managers and planers, we knew that there was a real customer demand for an automation system that is pervasively sensor-assisted and can be put into operation within hours instead of weeks.

Where does the name robodev come from?

robodev is a play of words for “robotic devices”, which stands for our aim of not selling yet another specific robot, but a modular set with which our customers can build individual automation devices that comprise modern robotics and artificial intelligence methods.

Which background do you have?

Before answering this question for myself, I want to emphasize that the important question is what are our backgrounds. Because without my two co-founders, Dr. Jens Liedke and Dr. Julien Mintenbeck, with their respective background in mechanical engineering and mechatronics, it would not be possible to succeed with robodev, whose products are at the intersection of mechanics, electronics and computer science.

As far as I’m concerned, I studied computer science and philosophy at the Karlsruhe Institute of Technology (KIT). Afterwards, I stayed in Karlsruhe to do my PhD in robotics and cognitive systems at the institute of Prof. Wörn, teaching a robot to assist a surgeon during minimally-invasive surgery – quite successfully. After a PhD internship at Google Research in Mountain View, I was offered a full-time position there and would have migrated to the Valley – had there not been the opportunity to co-found robodev.

When not working on building up the company, which I must admit is not a large amount of time at the moment, you’ll likely find me either in the Schlossgarten, reading, or up and down the hills of the Black Forest, biking or hiking.

You founded your startup robodev in 2016. How did you develop since then?

Most importantly, we talked to many (potential) customers and given their feedback, we iterated on our prototypes towards industrialized products. Furthermore, we exhibited prototypes of the robodev system at several industrial fairs, took part in startup competitions, pitched at a lot of different events and organized our first financing round. In the process winning two important awards besides the VC-BW pitch: WECONOMY and “100 Orte für Industrie 4.0 Baden-Württemberg”. Currently, we are getting everything ready for Hannover Messe 2017, where we’ll exhibit the initially available products of the robodev system.

How did you experience founding a startup here in the region?

Talking to entrepreneurs of older startups or companies founded a decade ago, the ecosystem for startups has improved immensely in the last years. We readily found offers for further education in business and entrepreneurial subjects, at KIT, CyberForum, IdeaHub and Wissensfabrik, and dedicated mentors that significantly helped us to get up to speed with all aspects of running a company beyond providing a great customers value based on a new technology. A big thank you to all of them.

Are there things you would do differently afterward when founding a startup?

It is still too early for a lot of hindsight wisdom. However, I would clearly go out of the lab even earlier and talk to real customers about their needs.

Recently, I read a lot about the „founder-burnout“: What do you do to prevent getting a burnout?

I can see the risk, as there is always one additional task you could do that appears to add to the companies success. I can not offer a silver bullet to this issue, but if one is honest to oneself, there are perceivable limits of personal work capacity, be it 60, 80 or more hours each week. It is okay to hit the limit and even to exceed it for a short period of time in crucial situations, but it is essential to take a step back from this limit under normal conditions – otherwise the limit is exactly the wall you are going to hit, sooner or later.

Which meaning does the award of the Venture Capital Pitch have for you?

Of course, we prepared our pitch and our exhibit in order to make it on the winner’s podium. Yet, in the past we found it difficult to get our topic across to an audience that does not necessarily have a background in manufacturing and factory automation. We are thus not only very happy about winning the award, but see this also as a positive feedback that the many iterations on bringing across our message have been worth it.

What are your further plans for the future?

As we are in a B2B segment, aspirations to making our startup robodev known in the general public are unfit. However, I think we have an offer that makes it quite possible to get to the point, let’s say in five years time, where, for a significant amount people, robodev comes to mind, when they are facing new challenges in their production facility – and we help them to perform these production tasks with our products.

Images: robodev Team, robodev System, robodev WECONOMY winner board © robodev GmbH; Portrait of Andreas Bihlmaier © Wissensfabrik/Slavica

Further Source: L-Bank

Leave a reply